METREKARE ALANDA

ÇALIŞAN

YIL TECRÜBE

Rusya Chestny Znak Markalama Çözümü | Data Matrix Kodlama ve İzlenebilirlik Sistemleri

Chestny Znak, Rusya’ya ihraç edilen ürünler için zorunlu olan dijital izlenebilirlik ve Data Matrix markalama sistemidir. Rusya’ya ihracat yapan üreticilerin, ürünleri üzerine Chestny Znak uyumlu Data Matrix kod uygulaması yapması yasal bir gerekliliktir. Teknosin olarak, Rusya Chestny Znak markalama çözümü kapsamında; içecek, gıda ve elektrik-elektronik sektörleri başta olmak üzere tüm ihracatçılara anahtar teslim kodlama ve markalama sistemleri sunuyoruz. Rusya Chestny Znak uyumlu kodlama ve markalama çözümlerimiz: Chestny Znak Data Matrix kodlama sistemleri Rusya izlenebilirlik sistemi ile tam uyumlu markalama Rusya ihracatı için zorunlu ürün markalama çözümleri Yüksek hızlı üretim hatları için endüstriyel kodlama sistemleri ERP, MES ve otomasyon sistemleri ile entegrasyon Rusya markalama regülasyonlarına uygun anahtar teslim çözümler Leibinger, REA Elektronik, Teknoprint ve endüstriyel lazer markalama teknolojileri ile; ürünler üzerine kalıcı, doğrulanabilir ve Chestny Znak uyumlu Data Matrix kodları yüksek güvenilirlikle uyguluyoruz. Hangi sektörler için Chestny Znak markalama çözümü sağlıyoruz? Gıda üreticileri İçecek üreticileri Elektrik ve elektronik üreticileri Ambalajlı ürün üreticileri Rusya’ya ihracat yapan tüm üreticiler Rusya Chestny Znak markalama sistemi, Rusya’ya ihracat için zorunlu bir regülasyondur. Uzman mühendislik ekibimiz ve sahada devam eden aktif projelerimiz ile üreticilerin Rusya markalama sistemine hızlı, güvenilir ve sürdürülebilir şekilde uyum sağlamasını sağlıyoruz.

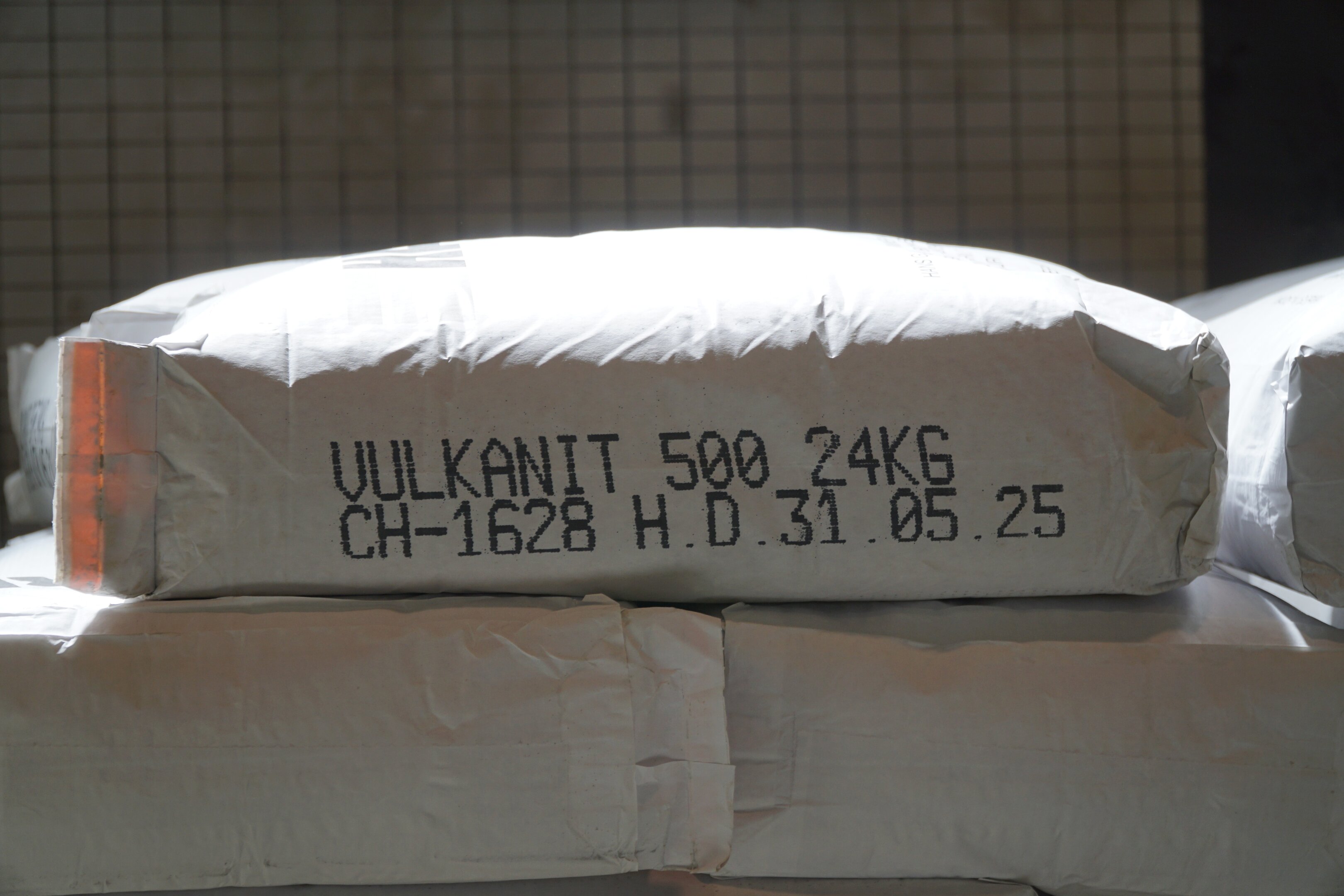

Çuvallara ve Torbalı Ürünlere Kodlama

Çuvalların ve torbalı ürünlerin markalanması, baskı etiketinin kalitesinden ödün vermeden etkili ve güvenilir şekilde yapılmalıdır. Dolu veya boş çuvalların markalanması, genellikle zorlu ve teknik açıdan talepkâr koşullar altında gerçekleşir. Bu koşullar arasında şunlar öne çıkar: Yüksek toz oranı Sıcaklık dalgalanmaları Titreşimler Bunlar istisna değil, endüstride çoğunlukla standart çalışma koşullarıdır. Ancak bu zorluklara rağmen, REA JET DOD 1.X sayesinde keskin ve kolayca okunabilir baskı sonuçları elde etmek mümkündür.2027’de GS1 Kod Zorunluluğu Başlıyor

Ambalaj üzerindeki kodlama ve markalama talepleri her geçen gün artıyor. 2027 itibarıyla GS1 dünya genelinde 2D kodların kullanımını önerecek. Bu yeni nesil kodlar; parti numarası, son kullanma tarihi, izlenebilirlik verileri ve daha fazla bilgiyi taşıyabiliyor. Bu nedenle birçok şirketin teknik ve organizasyonel olarak ciddi uyum sağlaması gerekecek. Erken hazırlık yapan firmalar, geçici çözümlerden kaçınarak süreçlerini güvence altına alabilecek. LEIBINGER sistemleri, değişken verileri gerçek zamanlı işleyerek makine tarafından okunabilir kodları yüksek güvenilirlikle uygular. Üstelik stabil, hassas ve maliyet açısından avantajlıdır.